A busy week and weekend means our blog is delayed again! It’s definitely harder to fit in everything that needs doing at the moment – it’s a constant battle to prioritise – especially when it comes to our vegetable garden as falling behind generally means seedlings die and we lose a couple more weeks (this week the lettuce, rocket and chicory gave up because we couldn’t pot them up fast enough…).

We had our monthly site meeting on Wednesday with our builders and architect, where we go through progress in the last month, any outstanding actions from the previous month, and then we run through what’s coming up. Most of our conversation focused around what to expect when work starts on the farmhouse (on Monday 26th) which is a little harder than the other buildings because we’ll be living (and working) in it as the build is completed. We’re more worried about the dust than the noise as most of the work is on the top floor, but taking down ceilings is generally a messy job – and at some point the new bathroom and hot water cylinder will need to installed which could mean cold showers for a day or two! Generally though everyone seems happy with progress, which gives us lots of confidence.

One of this week’s last minute decisions was relating to the roofing felt. We’re restricted in the type of felt we can use because we need to allow bats to access the roof spaces, and most felt is made of material they get their claws stuck in. This leaves us with two options – an older felt that’s not particularly breathable and requires additional roof vents to allow the building to breathe, or a newer (more expensive) felt that doesn’t need venting anywhere near as much. The slate-style vents for the farmhouse are quite discrete so we can’t justify the additional cost, but the only ones we can find for the shippon’s clay roof are much bigger and will really stand out and look quite ugly. It’s unlikely they’d be accepted by the council (we’d need 16!!) so we’re going for the more expensive felt and the better aesthetic look on the shippon – not really a cost-justified choice but we need to keep both the council and the bats happy!

We’re also still waiting for a date to fit our electrical supply from National Grid ESO – our contact has been on holiday for two weeks and seemingly no-one has progressed things in his absence, despite chasing a few times. National Grid ESO are working with such long timescales post-covid there’s a chance they might not be able to install our new electrical supplies before the end of the first phase of build. Any interim solution will cost us more, so we’ll try again this week to see if we can secure a date.

On site our builders have been making progress with all three buildings. Our stonemason is expertly building up the stone walls in our garage building – it’s slow progress but the walls aren’t small and it takes him time to find the right stone and chip them into shape. Our second delivery of stone arrived on site (this time from the more expensive company) and are more suitable for our barn. It’s still frustrating that we can’t simply use our own stone because we can’t get to it, but the end result is looking really good, and hopefully we’ll be able to sell on our own stone at the end.

The shippon front wall is almost complete, and our builders have installed the concrete lintels over the doorways. Their next main job is to concrete the inner floor, so they’ve been flattening the floor with stone, laying red sheets that double as a radon barrier and a damp proof membrane, and then installing the reinforcing metal mesh ready to pour the concrete on. The sheets are huge so it must have taken some doing to lift each one, get them through the doorways and then put them in place. It feels like there’s a delivery of materials almost every day at the moment – whether that’s stone, brick, metal sheeting, wood or something else that’s required that day. The deliveries tend to arrive on the day the materials are used because we don’t have enough space to store them for days on end – it must be a real mission to time everything.

And in the old hay barn, the stud walls have now gone up at one end, so you can really visualise what the rooms are going to feel like. Although the roof lights are in, the building still won’t be fully weatherproof until we get the main windows and doors in – hopefully we’ll have a date for the windows this week.

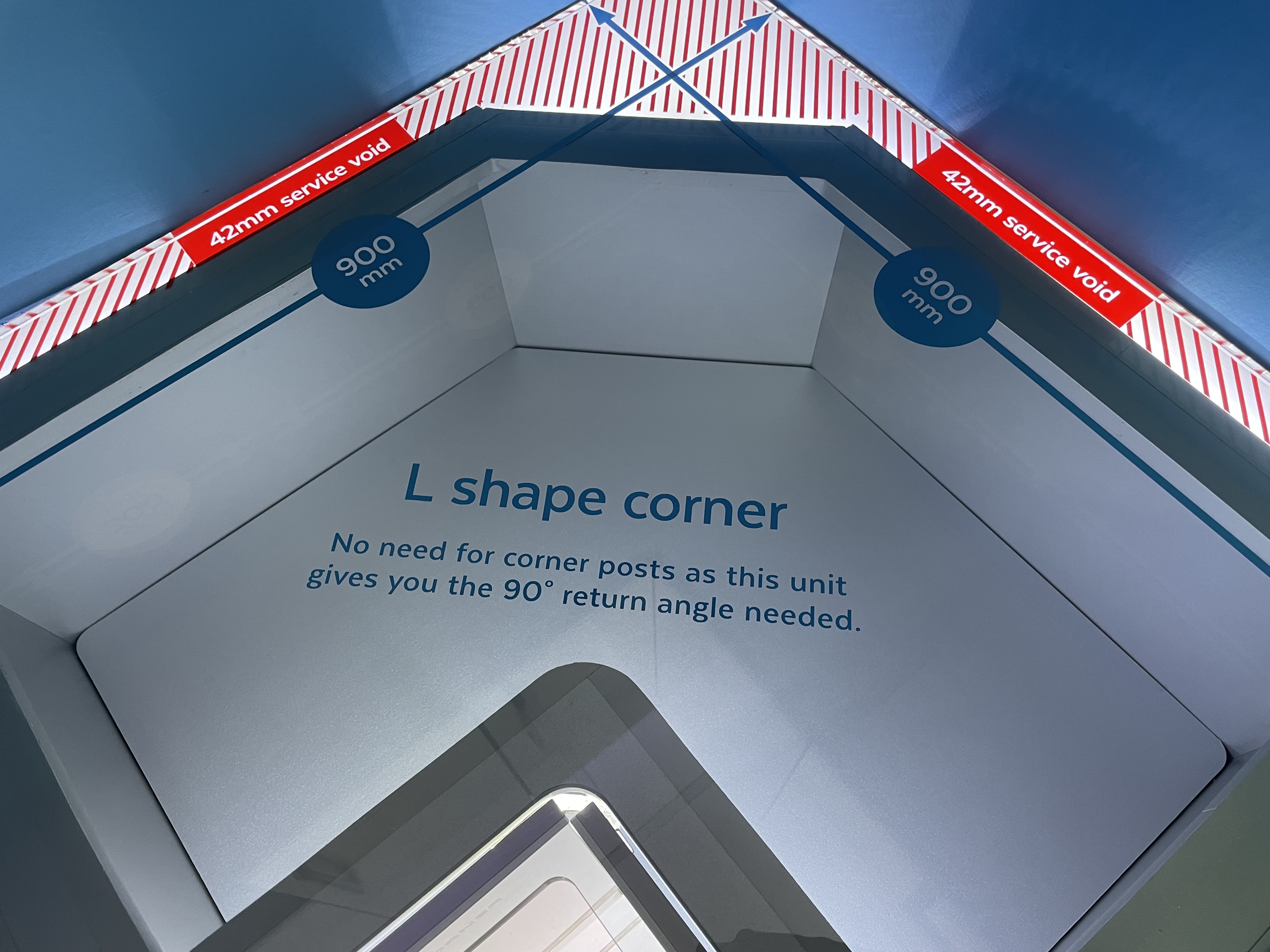

Although we were away at the weekend, we conveniently happened to be driving past the DIY Kitchen showroom in Leeds, and so stopped in to have a look. We’ve designed our kitchens using their planner, and even though we’ve not decided who we’re going to use to supply them, it’s been a fantastic tool to explore our options, and we’re very glad a friend of ours suggested them. We thought we’d be there for an hour – which turned into three! We completely changed our minds on the style of kitchen we wanted (previously modern flat cabinets but now shaker-style in keeping with the farm feel) – and we also changed the layout of our kitchen to give us more access room in the cupboards. We do have a bit longer to finalise the kitchen layout but we need to decide on the location of our underfloor heating manifolds, and were recommended to put these in the service void behind the kitchen cupboards, which drove the urgency for the kitchen designs. Not long now and we should be able to tick kitchens [or ours at least] off the list.

We did have a short-lived exciting moment with the garden birds this week. We’re still seeing plenty of baby blackbirds and sparrows around (the starling families left when we stopped putting out fat balls every day!), and we saw a family of about 5-6 baby pheasants the other week – our first ever! Sadly this week we’ve only seen 1 left with the parents, and have been carefully trying to feed it without inadvertently feeding the rats we’re getting rid of. Since we’ve been back though, we’ve only seen the two parent pheasants, and are desperately hoping the baby is still alive somewhere and just hiding…